Home > Our Products > Filling Machines > Automatic Filling Machines > Mini Monoblock

Mini Monoblock

When a UK-based spirit manufacturer tasked Karmelle with designing and manufacturing a machine unique to the UK, we were happy to oblige.

The company needed a system with a small footprint, capable of filling, capping and labelling a high number of miniature containers at a fast pace.

We decided to take on the challenge because we knew that, if successful, it would be the perfect solution for many of our customers. Soon, the Mini Monoblock was born.

The Mini Monoblock:

Karmelle’s Mini Monoblock is a volumetric rotary filling machine, complete with integrated capping machine. It was designed to fill 10ml-50ml containers at a rate of up to 30 pm (dependent on volumes).

The machine is of fully stainless steel construction, and can be fitted with an in-feed conveyor of 82.5mm width (100mm working), or a separate feed system.

How does it work?

Containers are first fed into a star wheel, before entering a filling station. From there they are passed through another star wheel to be capped.

Following capping, the containers can be fed back onto a second conveyor and passed into the labelling machine.

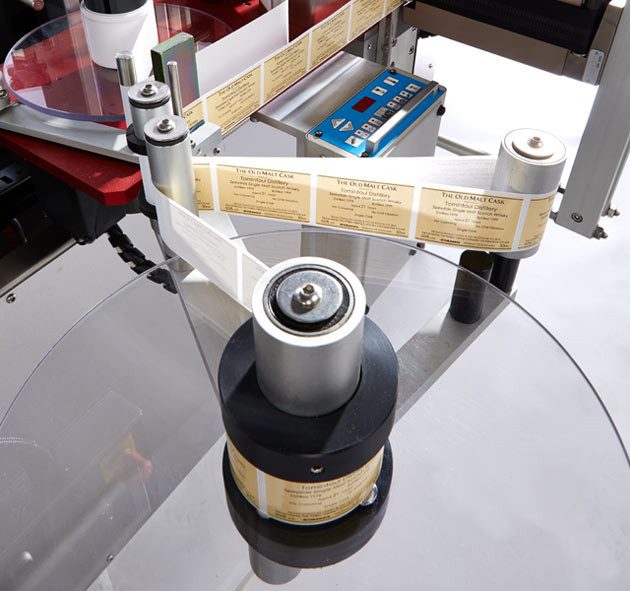

Applying a single wraparound label:

The leading edge of the label is applied to the side of container as it passes into the labelling station, which in turn spins it against a set of revolving rollers, wrapping the label firmly around the bottle. Accuracy of placing +/- 0.5 mm.

The labelling head can be equipped with an open date hot-foil printer (which is capable of up to two lines of text) or similar system built into it.

The specification includes:

Stainless steel construction throughout

- The lower construction of the machine completely enclosed in stainless steel panels

- The upper construction consisting of stainless steel with clear lexan panels and openings

- Safety interlock door guarding to meet EC regulations

- Menu Driven HMI touch screen control

- Guard master safety relay and interlocks

- Pneumatic control will be full SMC specification

- High level control panel and HMI

- Omron PLC control

| Mini Monoblock | |

|---|---|

| Fill capacity | 10 – 1000 ml |

| Fill accuracy | +/- 0.5% |

| Fill speed | 30 ml @ 20 bpm estimated |

| Capping | Cap styles can either be Ropp or Standard screw cap. Automatic cap sorting and placing |

Labeller specification:

- 1 x Karmelle servo125 applicator

- 1 x 3 point wrap unit

- 1 x Cross-support bracket for adjustment of the labeller

- 1 x Cross support bracket for adjustment of powered wrap unit

- 1 x Product sensor

- 1 x Frame (stainless steel box section frame)

- All associated guides, rollers, sensors and brackets etc.

[/column]

Karmelle is a British manufacturer of liquid filling machines, capping machines, and labeling machines with over 35 years of experience. We supply custom-built, turnkey filling systems to a wide range of industries, including food and drink, pharmaceutical, cosmetic, chemical, and lube oil. Our machines are designed to meet the specific needs of each customer, and our team of experienced engineers is committed to providing a personal service.

PPMA registered member since 2006.

Home | About us | Products | Market Sectors | Contact | Sitemap

Karmelle Liquid Filling

& Capping Solutions Limited

Unit 17 Queens Mill Industrial Estate

Queens Mill Lane

Huddersfield HD1 3RR

West Yorkshire

United Kingdom

© Copyright 2024 Karmelle Liquid Filling & Capping Solutions Limited | All Rights Reserved

Company Registration No.: 4968981